Three-channel programmable gas mixer

GSM-3

- Mix any three gasses into custom blends

- Applications include control-of-breathing and hypoxia studies

- Accurate custom gas mixtures

- Wide range of gasses and flows

- Custom gas configurations at no extra cost

- Stored programs for immediate retrieval

- Stand-alone or computer controlled with supplied software

- Controlled flow range for any input gas: 10cc/min - 20 liters/min (Note 1)

- Flow accuracy (percent of full scale): +1.0%

- Flow setting repeatability: +0.15%

- Resolution: 0.1%

- Temperature coefficient: 0.05% / oC

- Pressure coefficient: 0.01% / oC

- Response time (to 0.2%): <1 second

- Materials exposed to gas: Delrin with Viton seals

- Standard gasses for input: Air, O2, CO2, and N2 (Note 2)

- Operating temperature range: 5 - 40° C

- Input gas temperature range: 0 - 50° C

- Minimum input gas pressure: 20psi

- Maximum input gas pressure: 100psi

- Gas inlet connections: quick push/pull 1/4” OD tubing connectors

- Gas mixture outlet connection: quick push/pull 1/4” OD tubing connector

- Analog gas concentration output scaling for each channel: 0.05V / %

- Serial data format: 9600 baud, 8 data, no parity, 1 stop bit

- Electrical requirements: 120VAC/220VAC switchable, 35VA

- Dimensions: 19W x 5.25H x 12D in., 49W x 13H x 30D cm

- Weight: 20 lbs. (9kg)

Note 1: Not to be used for Human Life Support applications.

Note 2: Many other gasses can be selected, except explosive mixtures, which MAY NOT be used.

The GSM-3 Gas Mixer creates custom gas blends from any three input gasses. A mixture is defined by a Total Flow, and the percent concentration of each gas. The resulting flow for each gas is computed and displayed on the LCD display. Four user-defined mixtures can be stored locally on the GSM-3 and turned on/off with a pushbutton. Using the supplied GSM-CommVS software, any number of mixtures can be saved on the computer and recalled as needed. The GSM-3 can be operated solely with the front-panel controls, or controlled by the supplied software (see below). Each GSM-3 is customized with the most appropriate flow controllers for the intended application.

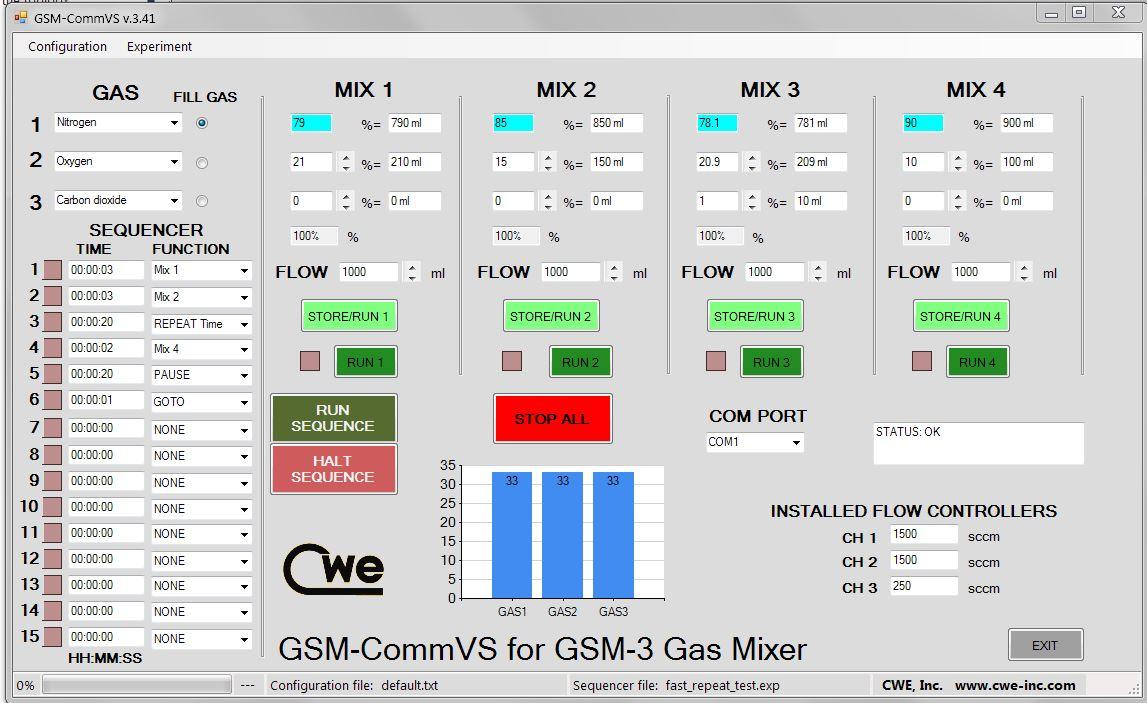

GSM-Comm Software

This software runs on Windows 7, 10 or later versions, and allows user-defined mixture configurations to be saved and loaded as needed. The Sequencer uses a simple programming language to perform timed protocols These timed sequences can be named, stored, and repeated as needed. This capability eliminates the need to manually switch gas mixtures for a particular experimental protocol. Each step in the sequence is programed with a TIME, and a FUNCTION selected from a drop-down menu.

With the exception of the Sequencer , the mixture parameters are defined exactly as they would be from the front panel controls of the GSM-3. Each mixture has a selected Gas,Total Flow and individual gas concentrations. Error checking prevents the user from setting up an invalid mixture. Any set of programmed mixtures can be named, saved, and retrieved for later use.

Most applications use one or two active gasses (eg. O2 or CO2) and a background gas (usually N2). This background, or Fill gas is selected by the user and is automatically computed to make up the balance of the gas mixture. This insures that the mixture components always add up to 100%. When a mixture is actively running, the bar graph shows the concentrations of the component gasses.

Each GSM-3 gas mixer is customized at no additional cost to you. If you have any questions about configuring the GSM-3 to meet your needs, please let us know. Our technical team is ready to work with you in determining the best flow control ranges required to optimally customize your gas mixer.